Imprint choices can be frustrating when buying printed bags. For customized reusable bags, there is no single best imprint process. It depends on your artwork, your brand, and your budget! Nowadays, we have four main imprint types: screen printing, full color, dye sublimation, and gravure. Below is a breakdown of each type of imprint.

Screen Printing

Screen printing is a common method of printing customized reusable bags. It works with most materials. Therefore, this process is a perfect choice for simple and bold artworks, logos, messages, and other arts with distinct lines and colors. Screen printing allows the colors to stretch along with the material, and in turn, means there will be less fading from general wear and tear.

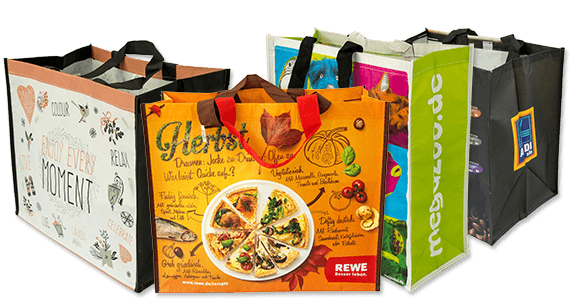

Full Color (Heat Transfer)

The full-color heat transfer imprint method uses heat to take your digital design and turn it into a vibrant, photo-quality finish. The method provides bright, clear, and flexible designs perfect for multi-color, detailed designs, and picture quality imprints. Full-color heat transfers do not require lamination, and an imprint area within the bag bounds these transfers.

Dye Sublimation

Dye Sublimation uses heat and pressure to transfer digital images onto fabric. The dyes permanently bond with the fabric, resisting the fading, cracking, and peeling that comes from other imprint types. Additionally, this process provides high quality, vivid imagery with a full range of colors. Dye sublimation provides an eye-catching promotional product and can work with intricate, detailed designs as well. The design can be printed seam to seam (full bleed).

Gravure

Gravure printing is a specialized process. It is a direct transfer method for printing onto bags. This process offers the ability to transfer ink consistently at high speeds, making it suitable for high image quality and large production runs.