Woven polypropylene sacks are considered to be the strongest, breathable, and extremely cost-effective packaging bags used to pack materials such as seeds, feeds, fertilizers, sand, metal parts, concrete, garden or document waste and many other applications. Woven PP bags are laminated inside or outside with a polypropylene coating, providing an additional barrier to moisture and liquid leakage, without hindering the options for easy-opening and re-closure. They are not just flexible, strong and reusable but waterproof and U.V protected against the sun.

Features

- Fabric weight from 65 gsm to 200 gsm

- Extrusion coated and uncoated versions

10 x 10, 10 x 8, 12 x 12 and 14 x 14 weave construction - Multi-color printing

Ultraviolet (UV) protection

Type of PP Woven Sack:

- Multicolour Printed BOPP laminated PP Woven Sacks/ Bags

- Coating

- Woven only

Applications of woven PP bags:

- Agricultural product packaging

- Food packaging

- Geotechnical engineering

- Tourism and transport

- Daily necessities

- Flood control products

- Specially woven bags

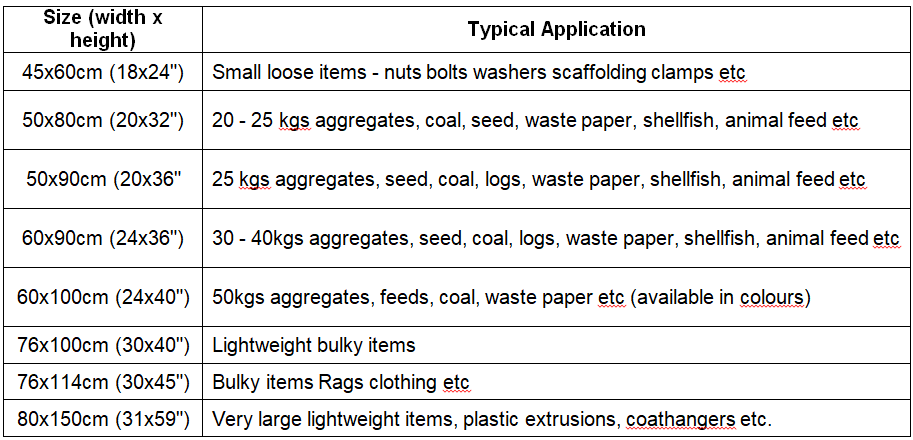

Some most common sizes of woven polypropylene bags for your reference

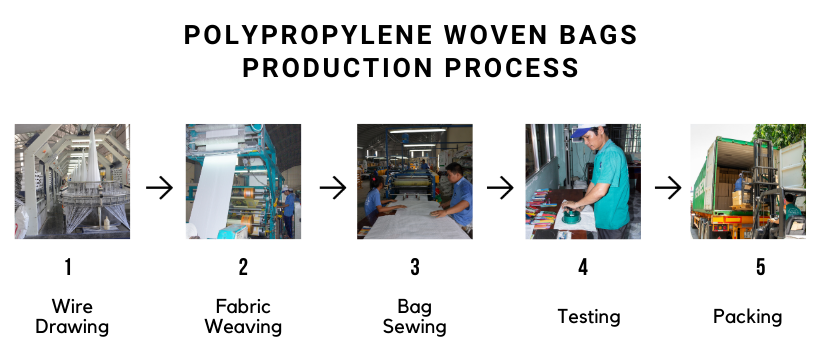

Manufacturing process of woven polypropylene woven sacks

If you are looking for a partner in Vietnam for Pp woven sacks, Sapphire is one of top reliable manufacturers you can work with. Let chat with us or send us your inquiry

.jpg)